| Parameter | Unit |

| X axis travel | mm |

| Y axis travel | mm |

| Z axis travel | mm |

| Table size | mm |

| Working table load | kg |

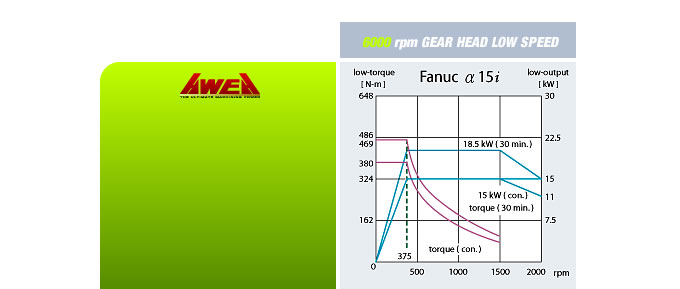

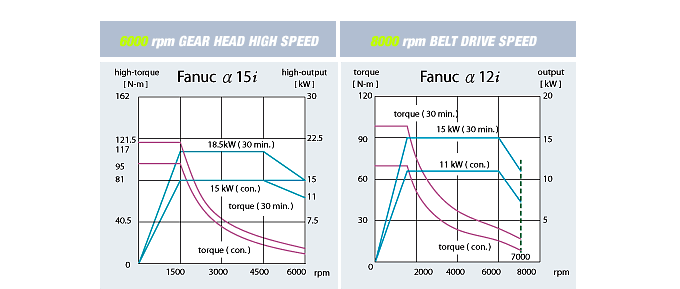

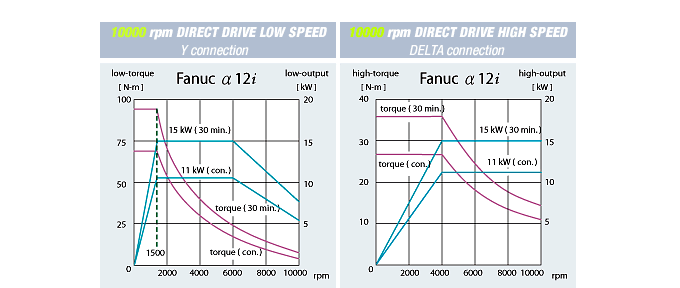

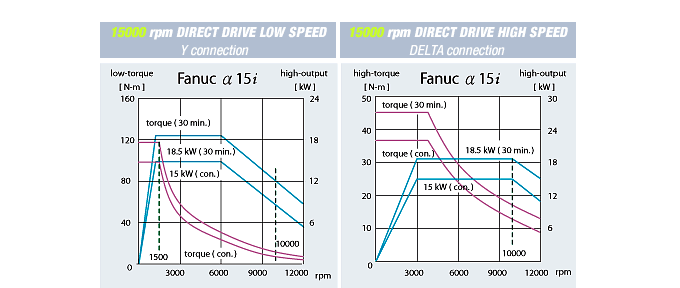

| Spindle speed | rpm |

| Spindle taper | |

| Spindle motor | kW |

| T-slot | no.mm |

| Max tool diameter | mm |

| Tool length | mm |

| Tool weight | kg |

| Tool change time | sec |

| Coolant tank system | L |

| Machine weight | kg |

BM-850 850 600 600 1050x600 850 65-1500 BT 40 11 18X5 110/200 300 15 7 265 6500

NC Intelligence

AWEA’s self-developed intelligent i Console software enhancement system provides you with a user-friendly interface, real-time machine status information and dialogic functions. It not only effectively reduces complex working process but also increases intelligent machining abilities.

Multiple Functions Status Display

- Real time operation information

- Tool list

- Work piece measurement

- M code illustration

- PLC function

- Calculator

- CNC optimize parameter ( Opt. )

- Spindle thermal compensation ( Opt. )

Trouble Shooting

When the alarm appears, the program will display the breakdown cause and a troubleshooting procedure. Users can easily troubleshoot minor problems to save machine shutdown time.

Circular Work Piece Measurement

The circular work piece program can calculate the center coordinate of a work piece by measuring point A, B and C coordinates.

Rectangular work piece measurement

The rectangular work piece program can calculate the center coordinate and the slant angle of a work piece by measuring point A, B, C, D and E coordinates; the calculated center coordinate can be inputted into the work piece coordinate program ( G54~G59 ).

Manual Tool Length Measurement

After manually measuring the tool length, the controller will automatically calculate the tool tip position and input the data into the tool length offset table.

Adaptive feed control

Adaptive feed control is capable of real-time monitoring the spindle load to control the axial feed rate which effectively extends tool life, shortens rough cutting time, and detects abnormal cutting conditions.

CNC parameter optimization

From rough cutting to fine finishing, the operator can select various cutting modes based on the working condition, and then set the allowable error and work piece weight to obtain the optimum parameter.

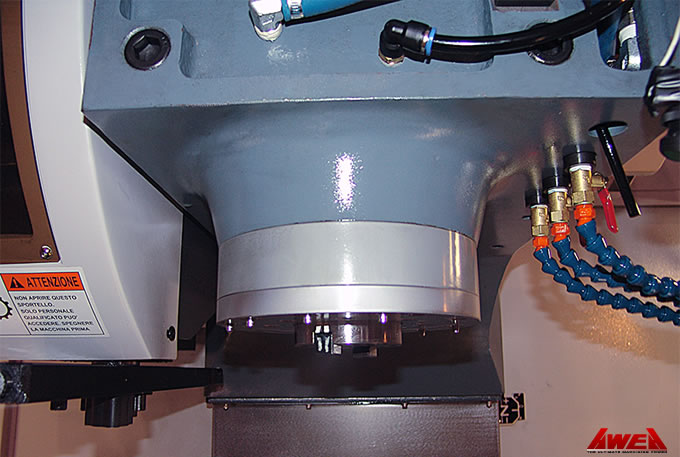

HIGH PERFORMANCE SPINDLE SYSTEM

AWEA offers an extensive selection of machining center spindle & motor configurations to suite your needs. From belt drive, to direct drive, to gear head spindles, we have them all. We also offer higher horse power motors to match the strength of our machines for the ultimate cutting performance.

Spindles are assembled in AWEA own clean room to eliminate contamination problems caused by the surrounding environment.

Geared spindles are manufactured in-house.

After assembly, complete head stocks are isolated, broken-in, and tested on test platforms to ensure temperature, vibration, and noise are all within specifications.

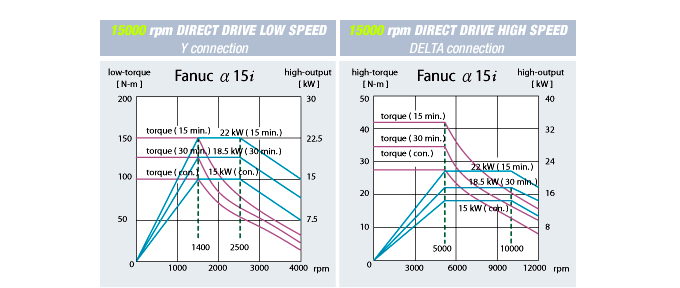

HIGH PRECISION DIRECT-DRIVE SPINDLE

40 taper size 10,000 / 12,000 / 15,000 rpm high speed direct drive spindle is available. The direct drive spindle provide higher rigidity ( 16 kgf / μm axial / radial ), higher dynamic accuracy (1.2 μm ), lower noise ( Doors open : 72dB / Doors closed: 63 dB ), less vibration ( 2μm ), and lower thermal displacement ( Z-axis steady @ 32μm in 30 min).

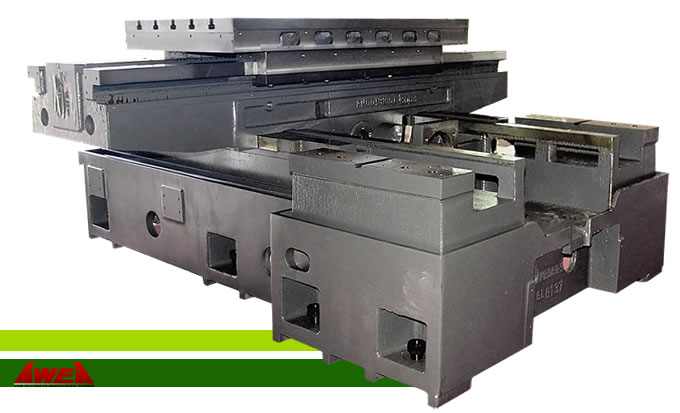

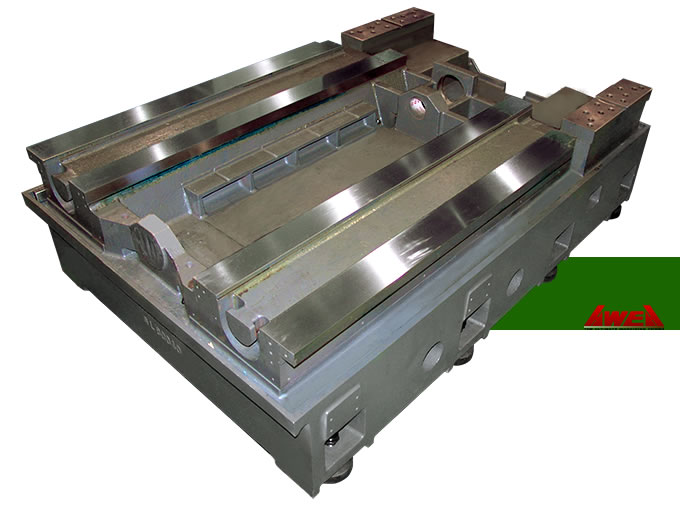

By using the Finite Element Method ( FEM ), optimal reinforce ribbings are directly cast into the one-piece bed structure. Together with the super-wide Y-shape column, mechanical rigidity has been increased by more than 45% when compared to conventional designs. The BM Series is capable of performing super heavy-duty machining and maintain long-term super high-precision accuracy. More rigidity also means extended tool life.

column ribs structure

Built to endure years and years of rigorous high production machining, the thermally balanced bed and casting components are of FC30 - Meehanite casting ( industry standard is FC20 ~ 25 ). FC30 grade cast iron is capable of withstanding much greater stress without deforming and provides maximum vibration dampening, which result in a machine that will outlast and outperform the competition.

The low center of gravity beds incorporate 4 wide box ways for the Y-axis, and are stretched to at least 1:1 ratio to match the lengths of X-axis travels. The 4 box way base offer support with no X-axis saddle over hang.

The rigidity of table is increased by rationally arranging the box type ribs structure.

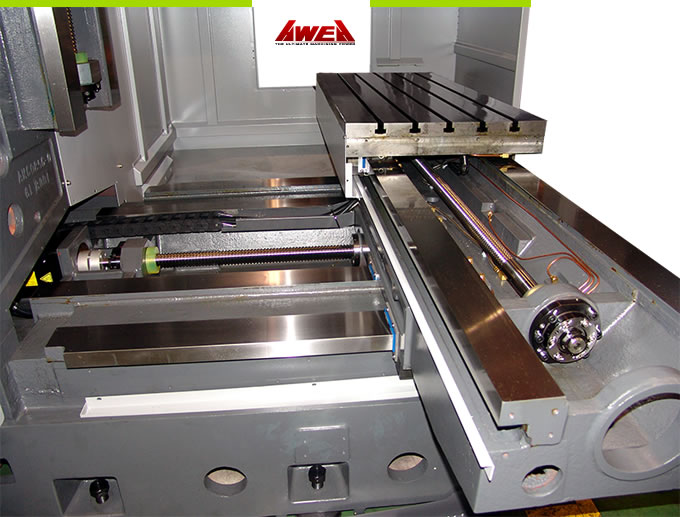

C3 class hardened and precision grinded ball screws ensure the highest accuracy and durable possible.

Plus, pretension on all axes minimize thermal distortion.

Extra wide hardened and grinded box ways are directly formed onto machine bed and saddle during the casting process. They are precision machined and widely spaced for maximum strength. Saddles are bonded with Turcite to eliminate stick-slip, minimize wear and maintain long term accuracy. The box way design also provides the rigidity needed for heavy duty machining applications.

A total of 56 contact surfaces of all slides, column, and ball screw bearing housings with the machine bed are precisely hand scraped to provide maximum assembly precision, rigidity, and load distribution. Furthermore, extensive skilled scraping induces maximum heavy cutting performance and machining accuracy.

Accurate ball-screw housing inspection

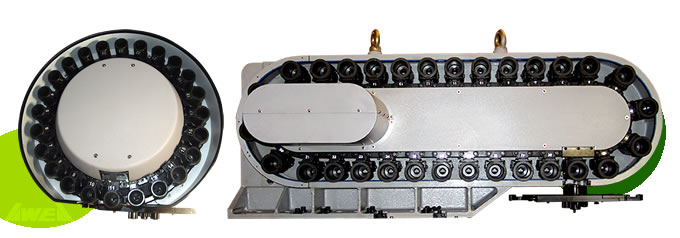

40-Taper machines have optional 24 / 30 / 32 / 40 tool swing-arm ATCs, 50-Taper machines have optional 24 / 30 / 40 tool swing-arm ATCs.

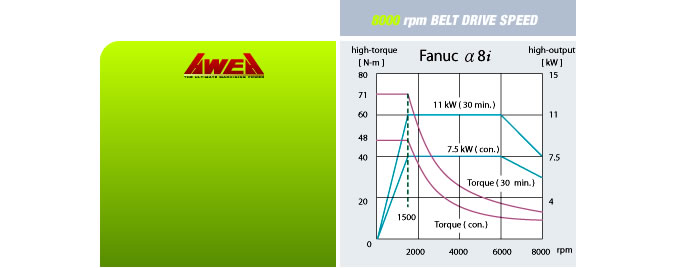

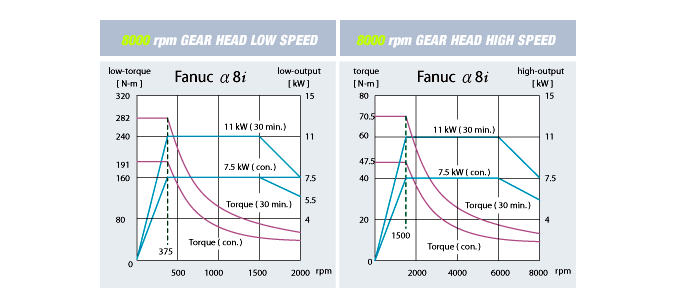

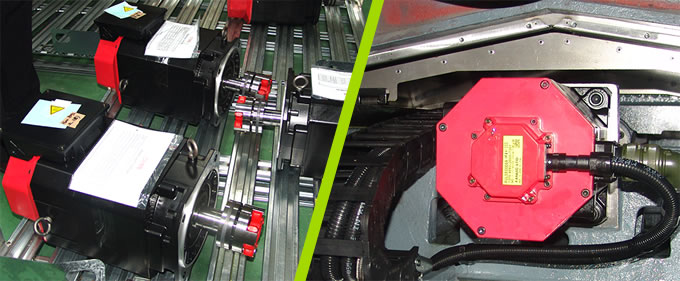

All spindle and servo motors, including drives, are Fanuc alpha i series components to ensure peak machining performance and accuracy. X, Y, and Z axes are driven by over-sized Fanuc alpha i series AC servo motors, providing tremendous thrust outputs with faster acceleration and deceleration.