| Paraméter | Egység |

| X tengely lökete | mm |

| Y tengely lökete | mm |

| Z tengely lökete | mm |

| Asztalméret | mm |

| Maximális munkadarb súly | kg |

| Főorsóvég - asztal tavolság | mm |

| Főorsó fordulat | ford/perc |

| Főorsó kúp | |

| Főorsó motor | kW |

| Szerszámtár kapacitása | |

| Max szerszám átmérő | mm |

| Szerszám hossz | mm |

| Szerszám tömeg | mm |

| Gépméretek (HxSzxM) | m |

| Géptömeg | kg |

MVP-4032 MVP-4040 4000 3200 1000 4020x2400 15000 200-2450 10-4000 BT50 22/26 48 125 400 25 11x8.5x6.2 50000 4000 4000 1000 4020x3010 15000 200-2450 10-4000 BT50 22/26 48 125 400 25 11x9.3x6.2 55000

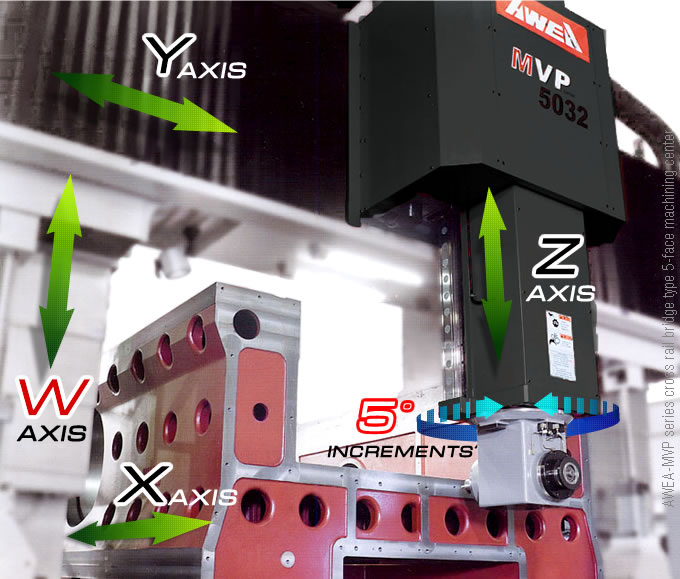

BRIDGE TYPE MOVING CROSS RAIL 5-FACE MACHINING CENTER

Packed with AWEA’s industry leading technology and high quality components, the MVP series double column bridge type 5-face machining center gives you automatic multi-face cutting power with maximum working range. Combined with rock-solid cross rail construction ( W-axis ), these series is provided with 1,250 mm large W-axis travel, 1,000 ~ 1,400 mm Z-axis travel, any-position automatic horizontal / vertical tool changer, and automatic optional heads exchange to fulfill all your work needs for today and tomorrow.

Super size double-column structure fully supports the cross rail to prevent structural distortion under long-hours cutting conditions.

The bed, columns and cross rail are adopted with high rigidity box structure design and applied with prolonged annealing process to assure a firm construction for high machining precision.

The main spindle, spindle motor, Z-axial ball screw, twin hydraulic cylinders and gear box are symmetrically placed to minimize thermal expansion and unbalanced torque while maintaining long term cutting accuracy.

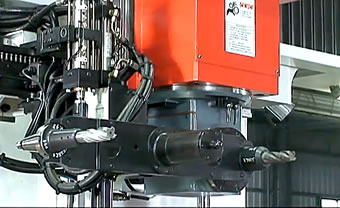

High efficient servo tool magazine can horizontally / vertically change tool at any position in the W-axis which greatly decreases non-cutting working time.

Standard tool magazine : 48-station arm type ATC (60-station ATC is also available ).

The LP series can be equipped with automatic head changer and vertical / horizontal ATC system to provide maximum efficiency as of a 5-face machining center.

Automatic head storage magazine provides two cabinets for both horizontal head and spindle cap. Linear guide way sliding design provides quick head change to reduce non-cutting time.

Based on your requirements, the standard 4,000 rpm high torque 2-step auto-exchange gear transmission can be optional equipped with either direct-driven spindle or built-in spindle to provide more cutting flexibility. ( Coolant through spindle is also available )

The high rigidity curvic coupling provides 5° increments ( 72 positions ) for maximum multi-faceted cutting capability.

The horizontal spindle head is adopted with oil mist lubrication system. Maximum spindle speed can reach up to 2,400 rpm.