| Paraméter | Egység |

| Maximális esztergálható átmérő | mm |

| Maximális esztergálható hossz | mm |

| Max. átmérő a védő fölött | mm |

| Tokmány méret | ″ |

| Rúd kapacitás | mm |

| Főorsó átmérő | mm |

| Főorsó fordulata | ford/perc |

| Főorsó motor | kW |

| Főorsó csapágyátmérő | |

| Főorsóvég | |

| Max. X1/X2 löket | mm |

| Max Z1 löket | mm |

| Max Z2 löket | mm |

| Vezérlés | |

| Hidraulikus / hűtő tartály kapacitás | L |

| Gépméretek (HxSzxM) | m |

| Géptömeg | kg |

GTS-200 GTS-260 Ø280 200 280 8 Ø51 Ø66 48-4800 11/15 Ø100 A2-6 190 270 740 FANUC 18i-TB 50/150 3x1.8x1.9 7800 Ø280 200 280 10 Ø65 Ø76 40-4000 11/15 Ø120 A2-8 190 270 740 FANUC 18i-TB 50/150 3x1.8x1.9 7800

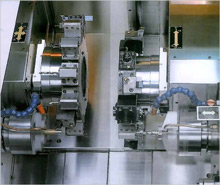

Two spindles and two turrets

The GTS series is designed for simultaneous cutting operations on two different workpieces with only one machine setting. The machines are built with two turrets and two spindles on opposite directions, the C axis having the possibility of being installed on both spindles and live turrets

The transfer of the workpiece between the spindles

The transfer of one workpiece from one spindle to another is done with the synchronization of both spindles. The accurate orientation is possible by means of controller on C axis. The result is the accurate relational positioning of operations on both spindles. The system does not require another calibration for phase adjustment, leading to a reduction of costs and cutting time

Main motors

For spindle driving two motors from the Fanuc Alpha Pi series have been selected, with a great power and extended torque, which can be programmed in order to synchronize the two spindles

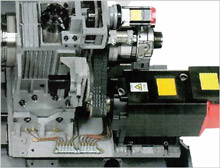

Two turrets

The turrets designed for heavy cutting have a servomotor driven indexing system, incorporating the “non-lifting” technology, so that the turret has no lateral movement during the cutting process. With an indexing time of 0.2 sec for adjacent toolposts and 0.5 sec for opposite posts, these are among the most competitive turrets in the world.

Bed construction

Built to withstand long years for accurate productions of parts, the bed is from Meehanite cast iron in one piece, heavily ribbed and perfectly balanced from a thermal point of view, with excellent damping properties and outstanding resilience.

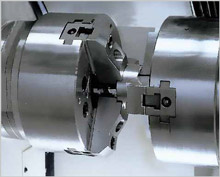

Stable high speed spindles

The headstock is designed for heavy cutting and is built from one piece of Meehanite cast iron, equipped with outer ribs, which both reinforce and cool.

Fanuc controller

GOODWAY uses the latest control technologies, equipping the GTS series with Fanuc 18iT as standard. This controller provides many standard features which either are absent or optional with other control systems.